Sample Crushing

To obtain more access to areas of high interest within organic materials, for example plant seeds and stems, it is necessary to use a method to reach those areas without interfering with surrounding parts. In other words how can these areas be reached, all useful material be extracted or made free without damage and how to prevent it from (background) contamination? The answer is to look closely at each sample and determine which methods are available for extraction in its best way.

Field experience and intensive testing have led to the development of usable products to deal with the above mentioned problems and are ideal for tissue extraction for samples to be used in ELISA and PCR.

Crushing was found as a method to make samples brittle and give them a more open structure. Open enough to let a solvent reach those enriched areas within the sample base material. But, depending on the kind of sample material, crushing in an uncontrolled way introducing also another problem. Parts of material that are not of interest could be crushed too, if the crushing force was to high, and setting free particles that could disturb the intended tests. For instance lattice or tomato seeds have certain substances within their protective outer shell that could disturb the research result of the core of the seeds. Therefore, again depending of the sample material to be processed, the most efficient way of crushing must be chosen. Generally, two products were developed.

Electric Sample Roller Mill VESRM-3

A compact vertically placed roller mill capable of crushing most plant material such as phalaenopsis or bulb samples. Each sample is placed in a ridged ordinary sample bag and is fed through the roller mill. The sample bag is positioned vertically with its opening up side to prevent moisture from the sample material leaking out. The usage of sample bags will eliminate cross-contamination and the need of intensive cleaning of machine parts.

The VESRM-3 can be used manually or in an automatic mode and has a capacity of crushing up to 900 samples per hour.

This fast and easy to use production machine is available with an optional movable undercariage.

|

|

|

|

|

|

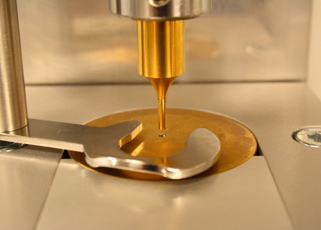

Electro Pneumatic Sample Crusher EPSC-3

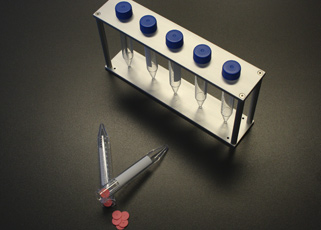

Opening or homogenizing of sample material in a more delicate way is achieved by using the EPSC-3 system. This electro-pneumatically driven system is capable of processing a wide range of seeds and leaves. The user can set parameters such as time and crushing pressure.

Universal extraction bags are filled with a specific amount of seed and are placed inside the machine to be processed.

|

|

Because pneumatic driven machinery is using compressed air, it is sometimes not advisable to use in a clean laboratory environment. Therefore a fully electrical driven version was developed: ESC-3

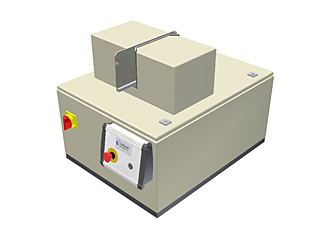

Electro Pneumatic Sample Crusher EPSC-3 DUO

For large research facilities the EPSC-3 Duo, containing two process units, was developed. A fully electrical version is also available on request.

Dwarskulk 5

3151 ZD

Hoek van Holland

The Netherlands