Sample Cutting

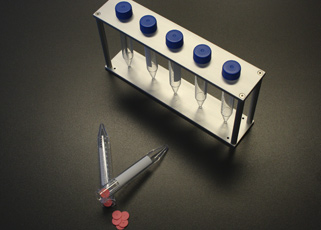

Within the Crop and Plant Quality Control industries large amounts of organic material are supplied to research centers for further examination. These amounts of batch materials must be processed according to several standards and protocols to determine if the crop is healthy or if there are any defects in the organic system. A common but important step in these processes is to take representative samples from the different batches.

For elongated items like stems of different plants this means cutting them in several pieces. Because there is such an amount of material available, cutting by hand is not an option. Therefore several cutting systems were introduced. Besides the ease of cutting the batch materials with these new systems, cross contamination can be prevented too.

The cuttingparts within the machinery which are in contact with the organic material, are easy to be cleaned and can be (dis)assembled within in short turnaround time, giving the lab technician more time to focus on the rest of the research process. Generally there are two models of the Electric Twig Cutter available.

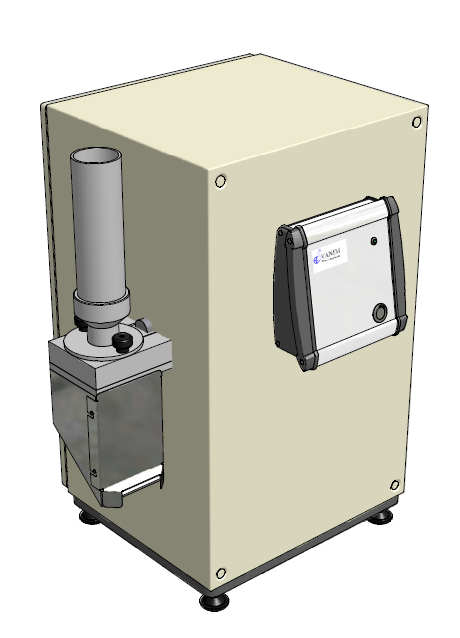

Electric Twig Cutter ETC-1

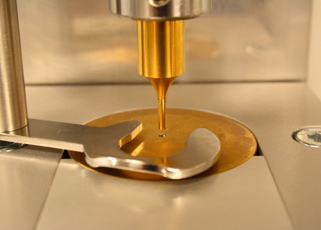

This small sized electrically driven cutting system is ideal for small batches with a max feed through of 30 mm. A sample cutting length is set by a mechanical stop and the batch material is vertically placed in the feed cone. A Cover Cone will hold the material down. When pressing down two start buttons at the same time, a specially shaped guillotine is driven through the sample material. The cut-off material is pressed away and collected by an Outlet Cone. The guillotine will retract and the batch material will be pressed down against the mechanical stop. The system is now ready for the next cut.

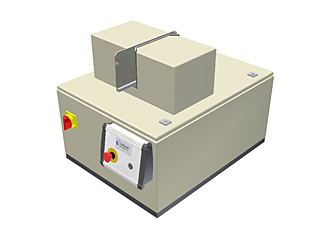

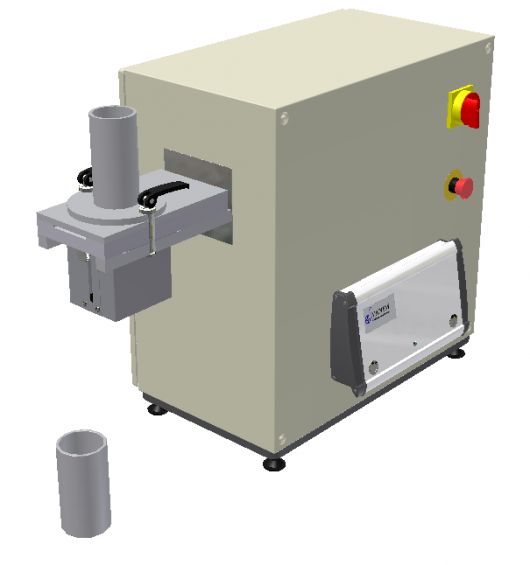

Electric Twig Cutter ETC-2

A larger version of the ETC-1 with a total feed through of 60 mm. S pecials versions of the ETC are available on request.

Dwarskulk 5

3151 ZD

Hoek van Holland

The Netherlands