Sample Punching

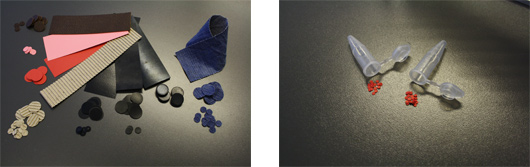

Sample Punching is about applying a concentrated force, by means of a punch, on the surface of a material. Depending on its consistency and thickness, the shear strength of the material will eventually allow a small piece of material to be separated from the rest. This sample can be used for further (pre-)processing or analyzing.

To achieve all this in a more labour efficient and result directed way, a range of automated Sample Punches was introduced. Each machine has his own unique possibilities and features. Besides the off-the-shelf models, specific custommade versions can be supplied too, depending on the needs of the user.

Generally the following models can be supplied.

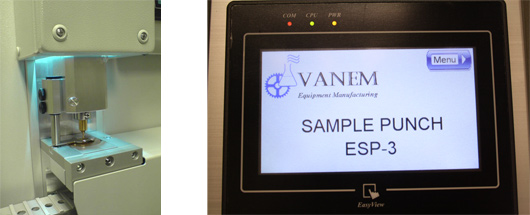

Electric Sample Punch ESP-3

A complete automated production machine with a punching capacity from 2 till 12 mm. Materials to be punched are placed on the easy to access and well-lighted punching table.

After the input of some basic parameters in the Control Menu of the touch screen, sample punching can begin. There is no need for an intense training course!

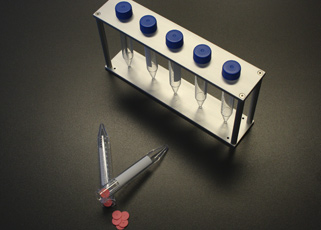

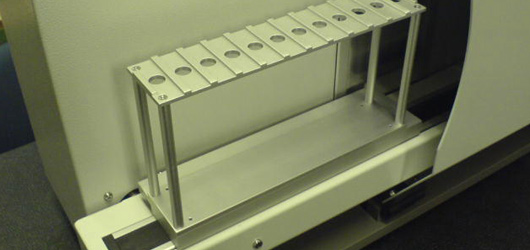

The punched out materials are collected in vials placed in a vial rack on an integrated drive system. You can choose how many punched out samples each vial must contain and how many vials must be filled.

Another unique feature of the ESP-3 machine is, it’s able to work with any type or brand of vials. There is no need to change your familiar brand or model. Simply let us know what type you are using and we can deliver adapted vial racks to adjust the machine to your needs.

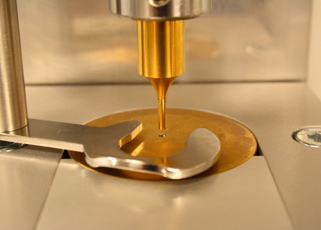

As an option the ESP-3 can be equipped with an integrated metering pump for dosing solvent fluids directly in the vials containing the punched samples. Depending on the kind of solvent needed, several pump systems and materials are available. Pre-heated solvent can be applied with a maximum temperature of 80 °C to prevent growth of bio-organisms in the solvent supply and storage system. This makes pippeting of the samples by hand afterwards obsolete.

The vial racks with their vials can be stored in buffer fridges to preserve the sample contents.

Electric Sample Punch ESP-4

This sampling machine has a punching capacity starting from 12 till 24 mm and is especially used for pre-sampling fiber containing materials or for large volume tests.

The ESP-4 can also be equipped with a dosing system for solvent fluids.

Deployment of ESP machinery

Generally the ESP machinery can be used for:

Quality Control of dry materials

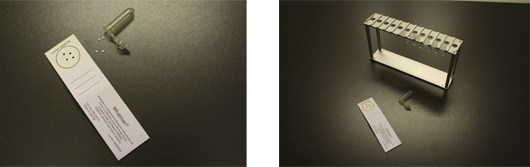

Sampling of dry, DNA containing materials (FTA Cards)

Quality Control of Crops or food related products.

Accessories ESP Sampling Machinery

The accessories of the ESP machinery consists generally of

- punch sets

- sample catchers

- injection needles

- pump heads

- dispensing hoses

- miscellaneous dispensing parts

- customized vial racks

When working with an ESP, the only disposables that are used are the vials that are already present within the research facility. There is no need to buy a specific type of vial, thus saving money and approving good housekeeping within the lab!

Environment

The ESP machinery concept is based on the idea of using less disposables within the research industry by adapting ESP parts to already widely available disposables!

Dwarskulk 5

3151 ZD

Hoek van Holland

The Netherlands